[ad_1]

Because the solar rises over Auroville, in Tamil Nadu, Harish Chandra, a local of Uttarakhand will get began together with his day.

The routine has been constant for the previous 30 years for Harish who got here to the city when he was simply 18, to check textiles and handloom as a part of an trade program by the Sir Aurobindo Ashram.

Chatting with The Higher India, Harish says whereas he entered the city in 1993 pondering he would keep for a most of six months, he by no means went again and Auroville turned his dwelling.

The textile program that he was engaged in had such an affect on him that he determined to construct the remainder of his life and profession right here. Right now, the results of that call is his enterprise Natura which sells a spread of homegrown pure self-care merchandise.

The beginning of an natural model

It’s an attention-grabbing story that made him shift his focus from textiles to the self-care business.

Recounting it, Harish says in 1998 two foreigners visited Auroville with a bar of cleaning soap and a promise.

On the time, selfmade soaps appeared a luxurious of types because the Indian market was full of chemical variations. The selfmade soaps that the foreigners introduced with them had the city intrigued, at how pure soaps might odor so floral and good.

So enthused and intrigued was Harish that he determined to experiment in his own residence with vegetation and oils from the close by gardens and create an ayurvedic model of cleaning soap.

Reminiscing the journey, Harish says, “The transition from handloom and exporting clothes to now making soaps have been very pure, and in time I constructed a enterprise Natura out of my experiments.”

Natura was based in 2000 with a workforce of round 5 folks from the close by areas in Auroville and a producing house of 4,000 sq ft.

The small enterprise had a easy goal: to make pure soaps.

All substances are ‘edible’

Explaining the record of substances, Harish says the most important one is coconut. “Coconut is prevalent in south India and Tamil Nadu. Together with this, I additionally used castor oil, sesame oil, neem powder, rosemary, apricot, almonds, and natural cocoa butter,” he says.

He provides that he makes use of moringa for the soaps whereas tulsi and basil are important oils that go in.

“I don’t use refined oils, and thus I typically inform my prospects that the substances that go into my soaps are even higher high quality than what’s discovered within the kitchen,” he quips. The soaps have a shelf life of two years.

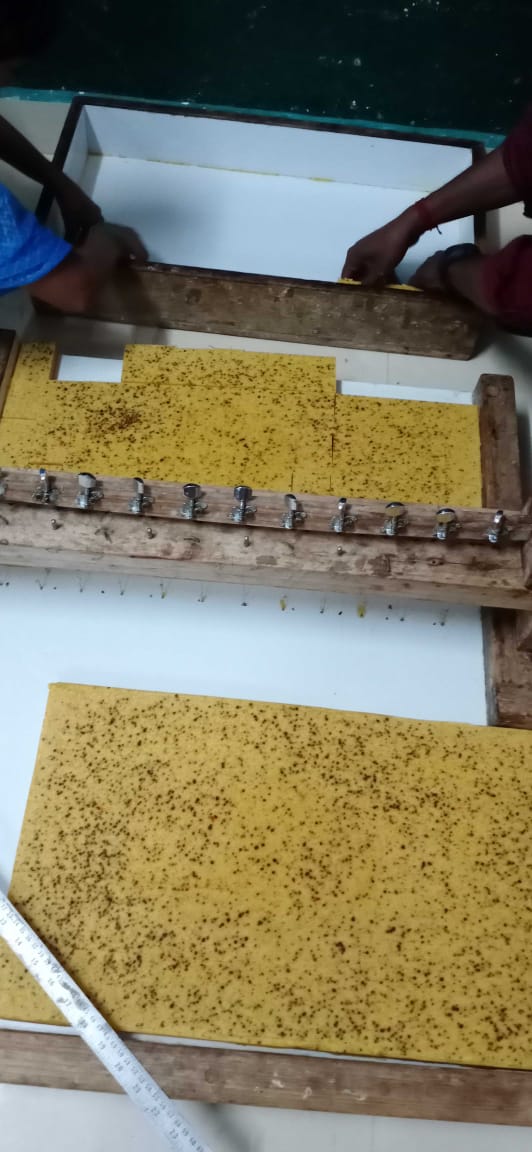

The method of making a single bar of cleaning soap is tedious owing to the natural method of manufacturing.

“We use a cold-pressed technique to make the soaps,” says Harish, including that probably the most essential half is calculating the substances that go into each.

“For example, my experiments made me realise that the quantity of neem that goes into the cleaning soap may be very minimal.”

Harish managed to give you greater than 30 variations of soaps.

The soaps as soon as fashioned in moulds are stored in an enormous enclosure on racks the place air flow takes place, after which the curing course of occurs.

A sustainable enterprise

Harish recounts that earlier than the pandemic they might pack the cleaning soap bars in plastic however they later started utilizing dry banana leaves as an alternative.

This whereas sustainable, proved to be a problem through the monsoon, because the leaves would degrade. Therefore, Harish selected utilizing butter paper or typically even glass jars to package deal and promote the cleaning soap.

He provides that Natura goals to have a zero-waste course of and therefore the leftover soaps are floor into laundry powders that can be utilized for the each day washing of garments. Harish has additionally ready an activated tooth powder made out of charcoal and bamboo.

The manufacturing unit could make 40,000 soaps per thirty days and Natura sees orders of round 800 soaps every single day. Their merchandise are despatched to Bengaluru, Pondicherry, Chennai, Kolkata, Himachal Pradesh and Mumbai. Their on-line platform ships internationally.

The merchandise are priced at increased charges in comparison with market requirements as they’re made with out chemical compounds. Whereas 1kg of the laundry powder retails for Rs 500, the cleaning soap bars begin at Rs 150, and the tooth powders begin at Rs 300 for 30 g.

Nevertheless, Harish says a problem that he faces is folks anticipating the merchandise to be priced at decrease charges.

“This isn’t potential as the character and substances of our soaps are totally different from these that are offered available in the market,” he says, including, “Available in the market, you should buy two soaps for Rs 20, however I exploit coconut oil and herbs within the soaps that make it luxurious.”

Edited by Yoshita Rao

[ad_2]