[ad_1]

The producers of the world’s first 3D-printed horse trailers, which might be available on the market subsequent yr, say they hope to fight provide, value and labour points, whereas producing autos extra shortly and precisely.

Double D Trailers, primarily based in North Carolina, US, introduced final week it was launching the brand new product, to an enormous response.

“Some folks had been saying ‘That is unbelievable’, others that we’re idiots!” proprietor Brad Heath informed H&H. “However it’s been overwhelmingly optimistic, and we’re actually excited to see the place this leads us.”

Mr Heath defined that since a automobile was totally 3D printed in 2014, the know-how has moved ahead in leaps and bounds; the aerospace and automotive industries utilizing it specifically.

Some 5 years in the past, he noticed Ingersol Machine, an organization in Illinois, had made a 3D printed boat.

“It was spectacular,” he stated. “I reached out to them and so they had the biggest 3D printer on the planet; I believe the price of the tools was about $3m. The prices had been astronomical.”

Since then, information of the most effective mixtures of supplies for power and precision has superior, Mr Heath stated, but in addition since then, the consequences of Covid have made themselves felt.

“The pandemic hit our manufacturing so we’re nonetheless 10 months out,” he stated. “If you’d like a brand new trailer, I can sit and discuss to you however I can’t do it for 10 months. Then there are provide chain points, and inflation – our prices have elevated 54% so a trailer than was $100,000 is now $154,000. Plus our unemployment fee is the bottom it’s been for 50 years and enterprise can’t rent folks. So after I revisited this a few yr in the past, I discovered it solves numerous the problems we’re dealing with.”

Mr Heath defined that each one the parts akin to latches, doorways and bolts will be printed in home, as an alternative of doubtless ready for weeks for a component to be delivered.

“We’ll print the ‘glass’ from a translucent materials that shall be sturdy sufficient to not break in case you hit it with a hammer,” he stated. “It’s fairly spectacular stuff.”

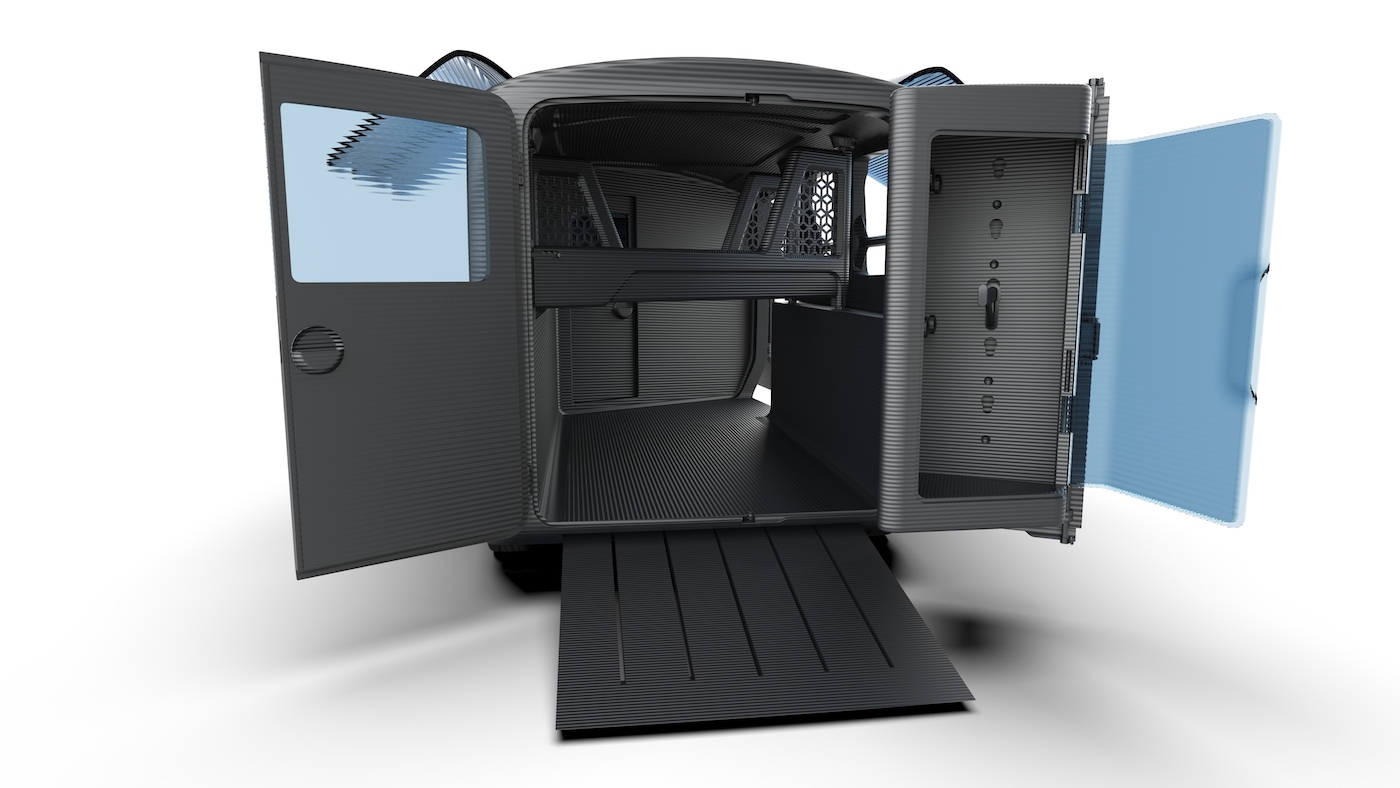

Double D Trailers has been working with reputed design firm One One Labs in Poland, and engineering agency Loci Robotics. As soon as the designs for the trailer and parts have been finalised, these are added to a pc system, and the designs despatched to the 3D printers. Pellets of the fabric used are fed into the printers and melted down, then the half hardens instantly it comes into contact with the air.

“Once I first talked to [the companies] they stated did I wish to weld collectively a metal chassis and print a field to go on high and I stated ‘Heck, no!’” Mr Heath stated. “We’ll arrange small machines to print the parts, and we are able to print as a lot element as we would like, right down to about 1/32 of an inch, however the primary construction shall be one print, with no seams, no joints. Then we’ll roll it into one other bay, and add the doorways, home windows and different parts.”

These embrace tyres, wheels and axles, about the one elements Mr Heath stated must be purchased in, which implies a smaller carbon footprint but in addition much less margin for error as there are fewer elements to be put in by hand.

Areas of the construct that must be stronger, akin to the ground, shall be printed at larger thickness. The ground and chassis shall be carbon fibre – “one of many strongest, lightest supplies accessible” – and the remainder polycarbonate and fibreglass fill.

The plan is to have a small, desktop prototype completed this month, and a full-size prototype this summer season, which shall be topic to “an incredible quantity of testing”.

“We’ll do our damndest to see what we are able to break and mess up!” Mr Heath stated. “In addition to seeing what temperatures it may possibly stand. Once we’ve completed, and might again up all our claims, at that time, we’ll be able to roll up our sleeves and say ‘You need one in all these? We’re prepared’.”

Mr Heath hopes the primary trailers shall be on sale in 2024, at a better worth in comparison with their conventional equivalents; extra like $70,000 than $50,000-55,000, however this may depend upon the ultimate value of the precise supplies used.

Ought to a part break, the shopper can order a brand new one to be printed from its particular design, and Mr Heath stated in concept, it needs to be attainable to soften down a complete trailer and reprint it.

“Possibly we’ll have a 10-year guarantee; if it’s totalled in an accident, for instance, we’ll simply grind it up and print it once more,” he stated. “We’ll nonetheless be making the normal ones too; it takes a very long time for folks’s mentality to vary, however we’re enthusiastic about the place this goes.”

You may also be taken with:

Credit score: .

Credit score: Jamie Ryder-Phillips

Credit score: Greg Balfour Evans / Alamy

Credit score: Future

Horse & Hound journal, out each Thursday, is filled with all the newest information and reviews, in addition to interviews, specials, nostalgia, vet and coaching recommendation. Discover how one can take pleasure in the journal delivered to your door each week, plus choices to improve your subscription to entry our on-line service that brings you breaking information and reviews in addition to different advantages.

[ad_2]